Vertech’s software solution helped yield .0001% measurement accuracy, handled 100ms of measurement rates per encoder and up to 5500 data points measured per test.

The new solution needed to analyze materials at the beginning of manufacturing process; read, store, and analyze measurement data quickly; transfer data from five linear encoders at high speeds; and store all data on a self-owned server.

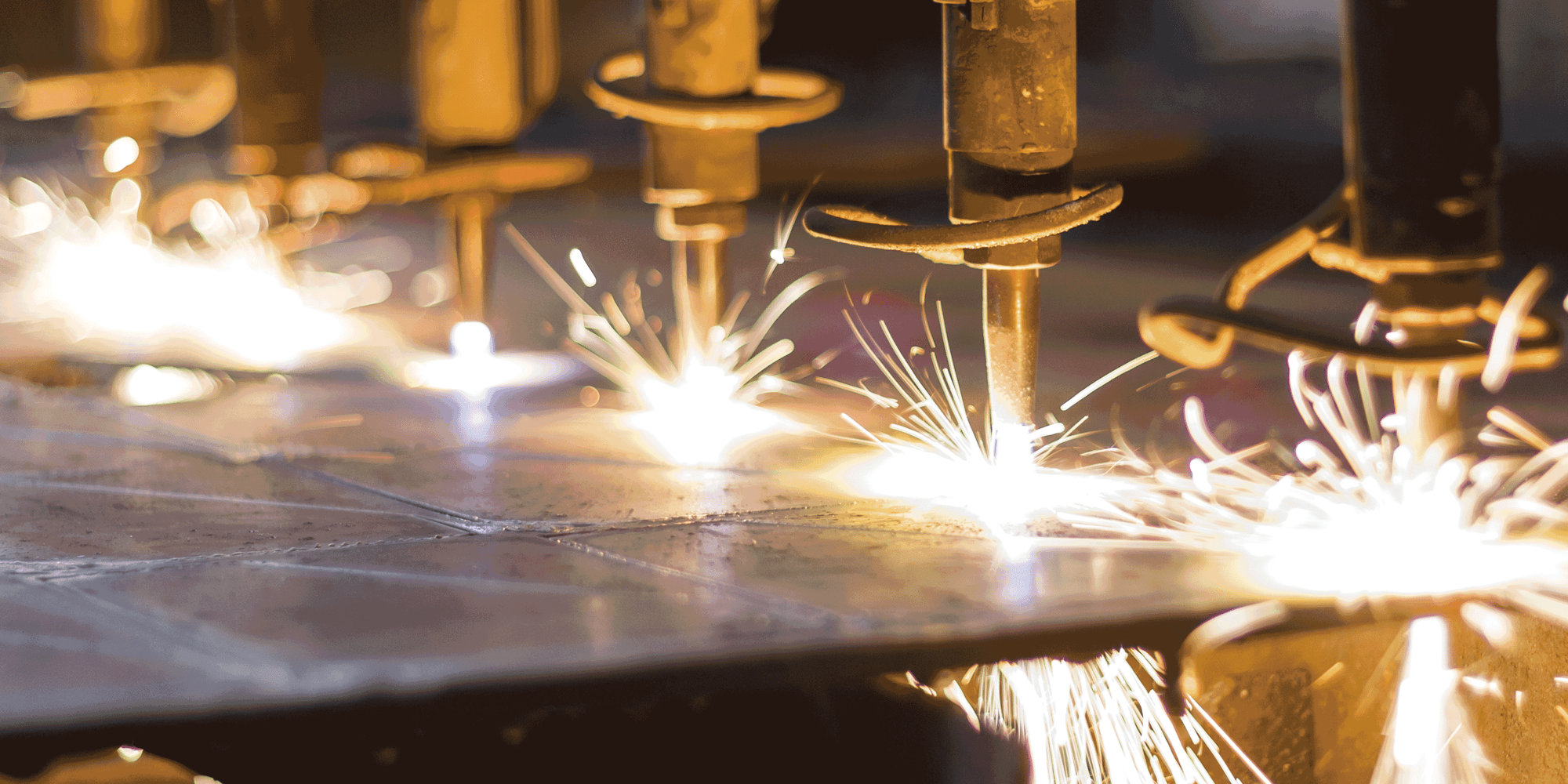

The client was looking for a way to increase their product’s quality and reduce waste by analyzing their materials at the beginning of their manufacturing process. Using a Siemen’s ET 200SP PLC they developed a machine that could measure the thickness and density of their products, but they couldn’t read, store and analyze their data quickly enough due to the software limitations. The client asked Vertech to develop a software package that could transfer data from 5 linear encoders at high-speeds, perform analytics & calculations with that data, and store all their data on their server for historical trends and future analysis.

Vertech developed a software solution using Siemens’ WinCC Open Architecture. WinCC Open Architecture provided the flexibility and power to transfer data at high speeds due to the event-based actions, complete analytics and calculations for the product’s test, and store all the data on to the client servers. Another benefit of WinCC Open Architecture is the software’s object-oriented features for data points. This allows scalable software for multiple machines as the client expands their facility.

Previously the client was using nine points of data to determine the thickness and linearity of their product. Although this information was helpful, it was not 100% effective in detecting failures. With the new system, the client is now able to read up to 5500 points of data per test, perform calculations faster, and store all data for future analytics. Overall, the client reduced manufacturing cost, increased product quality and invested in a system that can be easily expanded in the future.

“The expertise and support that Vertech provided during the development of our Super Mic SCADA project has been exceptional. They’re accessible, easy to work with - it’s a pleasure working with the Vertech team. We look forward to a continued partnership.”

4409 E. Baseline Rd

Suite 127

Phoenix, AZ 85042

(480) 756-2300

16 Technology Dr

Suite 118

Irvine, CA 92618

(949) 596-7986

2636 Elm Hill Pike

Suite 120

Nashville, TN 37214

(615) 356-7134

10801-2 N MoPac Expy

Suite 240

Austin, TX 78759

(512) 851-1109

©2022 VERTECH INDUSTRIAL AUTOMATION AND INFORMATION SOLUTIONS | PRIVACY POLICY | COVERAGE TRANSPARENCY